O firmě

Naše společnost B-Hořák s.r.o. byla založena panem Lubošem Bendou v lednu roku 2014, který navázal na své dřívější podnikatelské úspěchy a zkušenosti nabyté v době působení v renomovaných firmách ve strojírenském a kovoobráběcím oboru. Společnost se poměrně rychle zapsala do povědomí svou kvalitou a ochotou řešit i poměrně náročná technická zadání. Rok od roku rostla a modernizovala se.

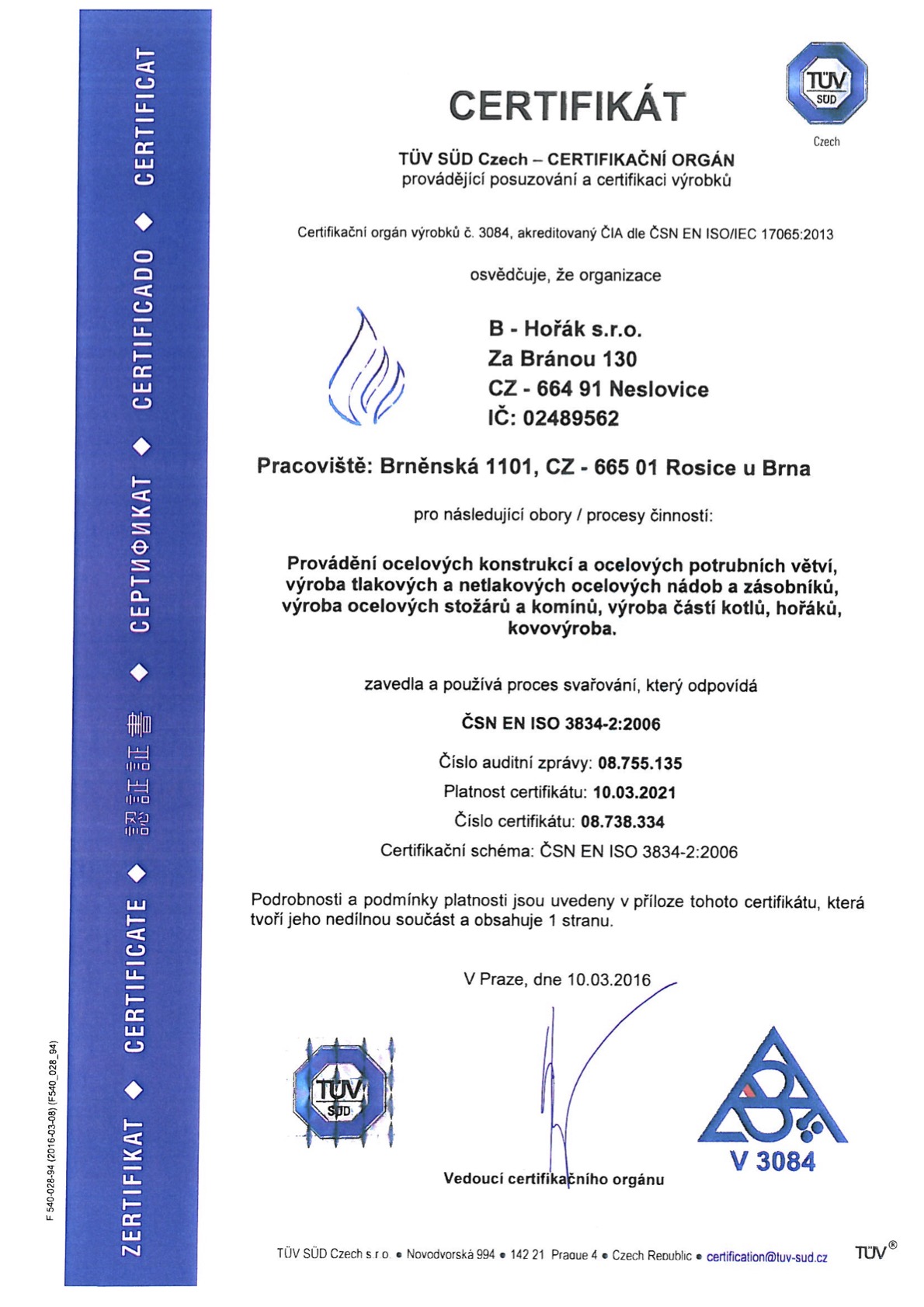

Získala ISO a certifikace SÜD TÜV EN 1090-1:2009, ČSN - EN ISO- 3834-2:2006, Directive 2014/68/EU, categorie I and II.